Epoxy Adhesive

V9500 is a two part black epoxy adhesive which has an operating temperature of -75°C to +150°C.

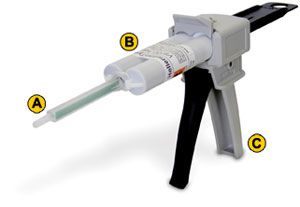

V9500 Breakdown: V9500 Nozzle V9500 DP (50gms) V9500 Applicator The Duo Pack Features Include: Qualified to VG 95343 T15A0001 Ideal for volume applications Accurate dispensing - no need for any weighing of components No mixing necessary when using the nozzle Less adhesive waste than 10 gram schalet bags Unique endcap assures proper sealing for multiple uses Positive locking of mixing nozzle

Product #: V9500

Specifications

| Field | Value |

|---|---|

| Peel Strength (XLPE/XLPE) | 25 lb/in |

| Shelf Life | The product should be stored in its original packaging at temperatures between +14°C - +26°C. Minimum shelf life of 24 months. For applications of adhesive see the code of practice which is available upon request. |

| Material Reference | V9500 |

| Relevant Spec. | Qualified to Def Stan 59-97 (Part 1) Issue 3 Type (U). Qualified to VG95343 T15A 0001 |

| Cure Time | Tack free condition in 24 hrs at +25°C. Heating the assembly for 2 hrs at +85°C will accelerate curing. |

| Dynamic Shear Backshell Boot/Cable Shell Size 22 | 120 lb at +23°C |

| Lap Shear Area (1/2"x1") (Metal/Metal) | 1364 lb at +23ºC |

| Thermal Shock Peel Strength | 4 Hours at +215ºC XLPE/XLPE 80lbs/Inch |

| Solvent Resistance | Excellent Reisitance to De-Icing Fluid, Petrol, Lubrication Oil and Hydraulic Fluid |

Application

| Field | Value |

|---|---|

| Applications | Excellent for fluid resistant applications. |